The significance and importance of drill tools can never be undermined as the success of a drill operation hinge largely on them. There are various types of drill operations that take place all across the world, for which different types of tools are used. Whichever be the operation, the drill tools are the most important part in determining whether the operation will be a success or not. Down The Hole (DTH) drilling is one such operation in which different set of drill tools is used. DTH drill string, air compressor and rotational drill rig are the tools which are used to perform DTH drilling. This kind of drilling is mostly applied in the construction industry to make the large piles into smaller, usable rocks by first drilling through them to convert them into flakes and then blowing them clear with help of an air exhaust.

All of these tools collectively work well to drill rocks, but the most important of them all is DTH drill string. It comprises of three vital components, which are the most essential in making sure a drilling operation goes well. Those components are DTH hammers, button bits and drill pipes. Each of the three has some specific functions to carry out, which starts from the pipes, carried forward by the hammer, and finally ended by the bits, resulting in the drill operation being performed successfully. The air compressor and the rotational drill rig do not really have a lot of work to do as most of the work is performed by the components of the drill string. All the three components, especially, drill pipe and hammer, need to work in unison to make the job done.

Drill pipes initiate the drill operation

The working mechanism of these components is pretty simple: all they do is make full use of the high air pressure and impact energy to drill. The first to come in the line of action is drill pipes, which due to its strong alloy composition is able to transfer the required feed force as well as rotation to the hammers and drill bits. As the hole gets deeper, more drill pipes are added for smoother drilling. The piston of it directly strikes the bits while the hammer directs and guide the bits, which results in the conservation of the impact energy that might have been lost had there been any joints present. The stronger the impact, the more powerful the DTH drilling is.

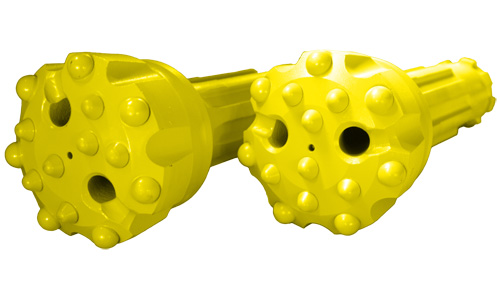

Finally, DTH button bits drill the hole

The DTH button bits, upon receiving the impact energy, rotational force and direction from the duo of hammers and drill pipes, start to drill the hole quickly. The conservation of impact energy results in much deeper penetration, which is why DTH drilling is regarded as one of the best drilling operations. Also, the recent advancement in the technology has resulted in the bits and hammers now successfully operating at a full tilt of 500 Psi, hence increasing the penetration rate.